Invasion of the Robots! Beware, Beware! Just Because We Can Doesn’t Mean That We Should…

AI, facial-recognition, machine learning… where should humans draw the line when it comes to automated ‘job theft’? Yogesh Patel gives it some thought.

AI, facial-recognition, machine learning… where should humans draw the line when it comes to automated ‘job theft’? Yogesh Patel gives it some thought.

Hammers, spanners, screwdrivers, scissors: tools of all shapes, sizes and functions have acted as catalysts for human progress — but could they also be our undoing?

We’ve defined past eras by the tools we used to forge them: stone, iron, bronze. In the thick of what we may as well call the Computer Age, our reliance on technology is exponentially increasing.

With the advent of automation, machine learning and AI, there are some distinct fears. Will all our jobs be taken by robots? Will super-intelligent AI depose us, and maybe even turn on us?

Starting with the least dramatic of those fears, yes, it is likely that some workers will be replaced by robots. Many thousands already have been, across industries and sectors. A report by consultancy firm McKinsey puts a positive spin on it with an estimate that as automatons arrive in the workplace (2015 to 2056), productivity will rise by 1.4 percent. Most jobs roles will be affected in some way, the report concludes. When it was written in 2017, however, it was assumed that changes would be gradual.

As with so many things, the Covid-19 crisis put many of those transformations on fast-forward.

Social distancing and quarantines have shown that resilient business strategies revolve around adaptability and flexibility. Many industries have had to reconsider the question of how robots could help to keep businesses afloat.

At Brigham and Women’s Hospital in Boston, Spot the Dog — the latest quadrupedal mechanical “canine” from Boston Dynamics — is being put to good use. Via remotely operated instruments attached to Spot, doctors are able to screen patients from a safe distance, all the while measuring temperature, pulse, and oxygen saturation.

In India, hospitals are using the robot Mitra — it means “friend” in Hindi — as a pastoral care assistant. It connects patients with loved ones via video link. Its slightly creepy, bug-out “eyes” house cameras for facial recognition of individuals it has met before. Mitra can also be used for remote consultations, a useful tool even without a pandemic.

Robots have also been used to improve hygiene, entering a potentially infected room and spraying disinfectant or shining ultra-violet light to detect bacteria or blood.

In China, December 2019, the concept was taken a step further. Companies such as Shanghai-based Keenon developed its vehicles to disinfect public areas using LIDAR (Light Detection and Ranging), machine “vision”, and sensors.

Other customer-facing professions have been given the android treatment. In Wuhan, e-commerce giant Jingdong Century Trading Co delivered packages via drone to relieve overworked warehouse staff. It kept goods moving in the remote shopping boom at the beginning of the pandemic — and the firm plans on soon rolling-out robot waiters at franchised restaurants.

But — as things stand, in employment terms — there’s no need for panic. Robotics companies are a long way from being able to pull a Skynet. But the sector is gathering momentum.

In 2020, China produced 31 percent of all robots manufactured — but many still require human operators. While complete automation of a complex role is still a way off — and may in some cases prove impossible — machine integration is not. Supplementing pre-existing roles with automated alternatives, in a push for greater efficiency, is on the horizon.

Data gathering and analysis are the type of time-intensive roles that benefit from automation. That 2017 McKinsey report notes that data-related activities then made up 51 percent of activities in the US, and $2.7tn in salaries.

While sceptics may see this as a loss for us mammals, it may be anything but. When US companies began outsourcing manufacture to Asia, its overall economic situation improved. Goods were produced at lower cost, and priced accordingly. The same effect could be seen with robots. Although they are expensive to develop and implement, the long-term costs are lower when compared with human workers.

The generation of machines that follow Spot and Mitra could be the breakthrough bots that change production as we know it.

You may have an interest in also reading…

The Exponential Growth of AI Computing Power: Trends and Predictions for the Next Five Years

The field of artificial intelligence (AI) has experienced remarkable growth in recent years, driven by advancements in algorithms, the availability

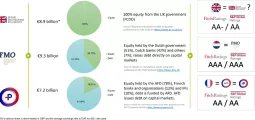

Bonds: Name of the Game for Cool (and Resilient) Operators

US corporate bonds certainly lack the thrill of that other famous Bond, James. But when it comes to strength and

Artificial Intelligence in FinTech

From Product Marketing, through RoboAdvice, Compliance and Fraud Detection activities, Artificial Intelligence is finding its place, but for the forseeable