Ginger Krieg Dosier: Biotech Innovation Traces Path from Marine Structures to Carbon-Neutral Concrete

Portland cement production accounts for eight percent of global carbon dioxide emissions, and uses 10 percent of drinking water. Concrete, of which cement is the vital component, is the second-most consumed substance in the world after water. Every second, 1,000 metric tons of concrete are used across the globe.

Biomason CEO and Co-founder: Ginger Krieg Dosier

“Biomason is the only company in the world using biology to commercially produce cement, eliminating the need to emit CO2 in production,” says Ginger Krieg Dosier, CEO and co-founder of Biomason.“We are curing the disease, instead of treating the symptoms.” Krieg Dosier and husband Michael, who serves as CTO, founded Biomason in 2012. Since its inception, the company has created biocement® materials aimed at creating a positive impact on the environment, from the manufacturing process to product performance.

“For millions of years, nature has used carbon as a building block for cementitious materials such as marine structures. While other cement technologies continue to rely on traditional methods of production, we at Biomason have learned to emulate nature’s blueprint of harnessing carbon to create cement in a completely different way. Our biocement technology grows in ambient temperatures, using natural microorganisms to create controlled, structural cement without emitting carbon.”

Krieg Dosier recalls her first moment of inspiration to grow structurally sound materials as a child studying a seashell. Now, the company takes a cue from coral reef systems to produce carbon-neutral cement. Its multi-patented biotech process combines naturally occurring bacteria, carbon, and calcium to grow biocement. Unlike traditional cement production, which requires calcination with kilns and can take up to 28 days to fully cure, biocement forms in ambient temperatures and reaches maximum strength within 24 to 72 hours. It’s also three times stronger than concrete masonry units.

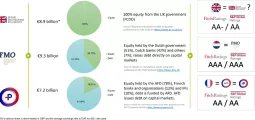

From 2013 to 2019, Biomason secured over $30m, including investor support from Novo Holdings, Martin Marietta and Noel Ventures. The company has seen tremendous growth over the past three years, laying the foundation to realise ambitious commercial and climate-action goals.

The Biomason team — 85 and growing and with over 50 different disciplines — moved in 2020 to a new headquarters and production facilities in North Carolina’s Research Triangle Park.

“Our recent additions of top-level experienced hires to our Executive Leadership Team have positioned us for continued acceleration and expansion,” Krieg Dosier told The Digest. “2021 has been an important year for Biomason; we’re rapidly scaling our technology and team and launching projects with global brand customers.”

Its first commercially available product, bioLITH® precast, is made from 85 percent granite from recycled sources and 15 percent biocement — and it’s paving the way to low-carbon building solutions across the US and Europe.

“Our precast tiles are in use in multiple projects, including at H&M Group’s Swedish headquarters and at Martin Marietta’s new Raleigh location. We are actively working with clients ranging from commercial companies and developers to innovative architects and designers worldwide to incorporate bioLITH and biocement technology into their projects.”

In partnership with the US Department of Defence, Biomason has developed a technology to create Engineered Living Marine Cement. Biocement is seeded with natural marine microorganisms that pull nutrients from seawater to propagate calcium carbonate structures, which results in sustained structural integrity, self-healing abilities and marine-floor anchoring. It has also developed an application to facilitate safe take-off and landing areas for military helicopters.

“As we look toward the future for Biomason, we have no intention of slowing down.” The goals encompass business development and continued technological advancement, she says. “Primarily, we are growing our licensed manufacturing and strategic partnerships, increasing profitability, and implementing additional biocement technology platforms.”

Rather than making incremental improvements on a 200-year-old formula, this revolutionary technology addresses the root cause of cement-based emissions. Imagine switching off the world’s kilns. Biomason aims to reduce 25 percent of carbon emissions from the global concrete industry by 2030.

“We are continuing to iterate and advance, because we know critical accelerated change is needed across multiple applications, as we are in a climate-change crisis. The potential uses for Biomason’s technology are vast, and we are eager to see them through.”

You may have an interest in also reading…

Dr Chitwan Malhotra: Healthcare Hands Meet Across the Waters in Push for Rebuild

The global pandemic has exposed the flaws and inequalities of the world’s healthcare systems. But doctor Chitwan Malhotra, the executive

SASB CEO Janine Guillot: Following Personal Passions Into the World of Sustainability

Janine Guillot, CEO of the Sustainability Accounting Standards Board (SASB), has an enduring love of the great outdoors that has

Ann Makosinski: A Beautiful Mind

Inventors don’t always make the best entrepreneurs. The skills and attitudes needed to develop new ideas are not the same